As New Zealand’s industrial landscape undergoes significant evolution, staying ahead of the curve is crucial for success in manufacturing. The future of industry is now being molded by emerging technologies and innovative practices that prioritize sustainability and efficiency. Recent reports illustrate how New Zealand manufacturing trends are increasingly focused on adopting advanced technology in manufacturing processes and integrating smart solutions to bolster production. With a commitment to innovation, New Zealand is redefining its manufacturing sector to thrive in a competitive global market.

Emerging Technologies Revolutionizing Manufacturing

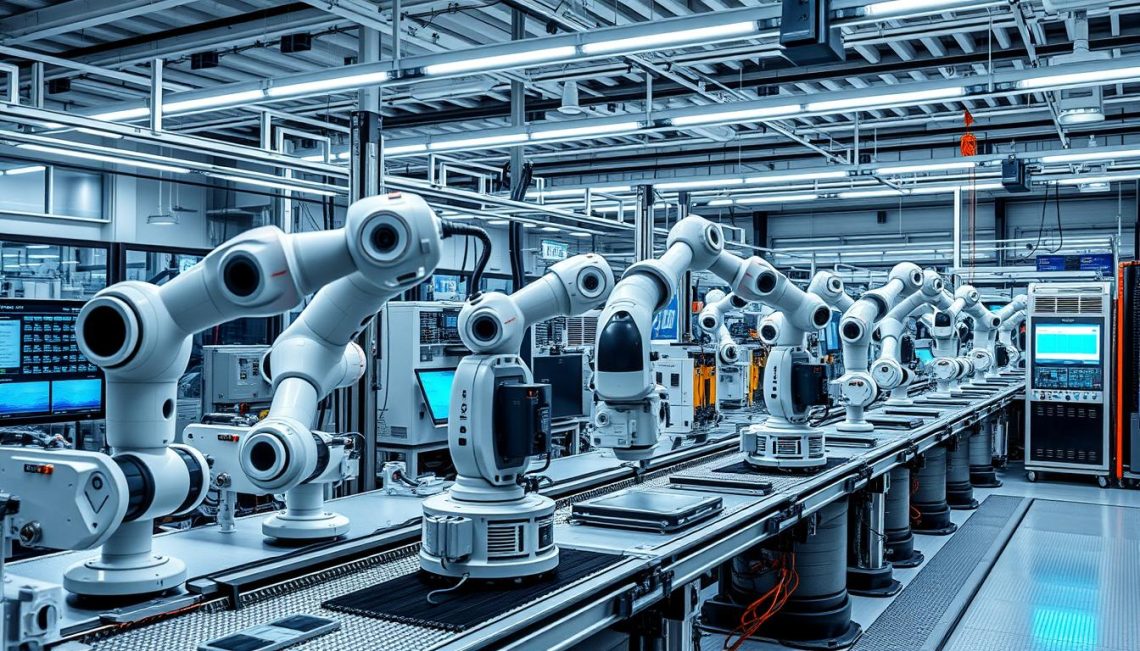

New Zealand’s manufacturing landscape is being transformed by the adoption of advanced technologies, particularly automation and robotics. This technological shift aims to enhance industry efficiency while positioning firms as competitive players on the global stage. As businesses recognize the importance of integration, they are investing significantly in robotic systems and artificial intelligence to elevate their operations.

Automation and Robotics Integration

Automation in manufacturing has become a cornerstone for companies striving to improve productivity and quality. Robotics in New Zealand is gaining traction as firms implement automated solutions to streamline processes. By incorporating robotic systems for repetitive tasks, human workers can redirect their focus toward strategic initiatives. Major corporations, such as Fonterra, are leading the way in this shift, leveraging automation to optimize production and enhance operational efficiency. The benefits of technology adoption include lower labor costs and improved precision in manufacturing tasks, essentially transforming traditional practices into smart factories.

Impact of Artificial Intelligence on Production Efficiency

Artificial Intelligence (AI) in manufacturing is reshaping how organizations approach production optimization. By utilizing AI technologies, businesses can make informed decisions based on data analysis, leading to significant improvements in process efficiency. Companies are integrating machine learning benefits into their operational strategy, employing AI for predictive maintenance, quality assurance, and supply chain management. These advancements contribute to reduced downtime and enhanced overall performance in manufacturing settings, showcasing the critical role of technology in New Zealand’s industrial evolution.

Top Manufacturing Trends Shaping the Future of New Zealand’s Industries

The landscape of New Zealand’s manufacturing sector is evolving rapidly, driven by sustainable practices, smart technologies, and adaptive supply chain strategies. These trends focus on improving overall efficiency, minimizing environmental impact, and enhancing responsiveness to market demands.

Sustainable Manufacturing Practices

Sustainable manufacturing is becoming crucial in New Zealand’s industries. Companies are increasingly adopting eco-friendly practices aimed at manufacturing waste reduction. Initiatives such as zero-waste production and renewable energy sourcing are integral to this shift. Furthermore, businesses like Z Energy are setting standards for accountability and sustainability through their innovative green technology approaches.

Adoption of Smart Manufacturing Solutions

Smart manufacturing represents a revolutionary change fueled by the Internet of Things (IoT) in industry. These advancements lead to optimized operations and real-time decision-making. Organizations are utilizing IoT devices to monitor processes and equipment, thereby boosting manufacturing efficiency and minimizing operational costs. The digital transformation in manufacturing paves the way for more interconnected systems, enhancing overall productivity.

Supply Chain Resilience and Flexibility

Recent global disruptions have highlighted the need for resilience in manufacturing. Adapting supply chains is vital for New Zealand manufacturers, enabling them to swiftly react to shifts in demand and material availability. Strategies such as local sourcing and diverse supplier networks are essential in building flexible supply chains. Effective risk management practices amplify these adaptations, ensuring businesses can thrive even amidst challenges.

Government and Policy Initiatives Supporting Industry Growth

The New Zealand government is actively implementing initiatives that aim to bolster the country’s manufacturing sector through innovative policies and strategic programs. Key government initiatives focus on fostering a robust ecosystem for manufacturing, which includes a comprehensive approach to industry support and technological advancements. The manufacturing policy is designed not only to enhance productivity but also to ensure sustainability across all operations.

Central to these efforts are New Zealand government programs that encourage research and development, creating a collaborative environment between public and private entities. These frameworks provide crucial funding and incentives that empower manufacturers to adopt cutting-edge technologies. With these resources, businesses can better navigate the challenges posed by a rapidly evolving global market.

In addition, strategic partnerships have been formed to promote knowledge-sharing and innovation among manufacturers. This collaborative approach not only strengthens the manufacturing sector but also contributes to a more resilient and adaptive economy. The ongoing support from the New Zealand government reinforces the commitment to industry growth, ensuring that manufacturers are equipped for future challenges.